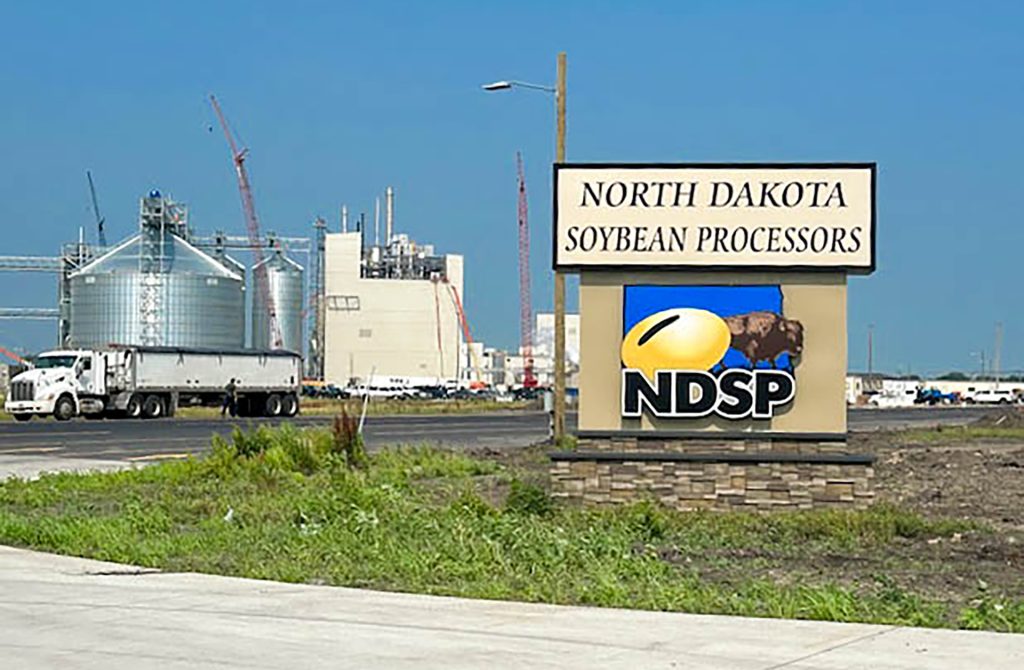

A dual-pipeline system spanning more than 25 miles is critical to advancing soybean production in the second-largest soybean-producing county in the United States. The new North Dakota Soybean Processors (NDSP) facility in Casselton, North Dakota will process 42 million bushels of soybeans annually. The location will reduce transportation costs for farmers by providing a local, year-round market. The facility will produce soybean oil for renewable fuel and food, alongside soy meal and pellets for livestock feed, effectively cutting soybean exports by 20% and creating local jobs.

A steady supply of high-quality, non-potable water sourced from the City of Fargo’s Regional Water Reclamation Facility (RWRF) and newly operational Effluent Reuse Facility (ERF) is key to its operations. NDSP will utilize a parallel pipeline system that transports water from Fargo’s RWRF and ERF. After the NDSP facility utilizes the water, it is returned to the headworks of Fargo’s RWRF for treatment.

The ERF at Fargo’s RWRF was designed with ultrafiltration and reverse osmosis membranes, capable of providing high-quality water with peak capacity of 570 gallons per minute for the NDSP facility. The membrane processes produce a concentrate waste stream, which is directed to the head of the RWRF for treatment. This approach avoids the need for discharge a concentrated waste stream into local water bodies, aligning with Fargo’s infrastructure capacities and enabling future industrial users to access the system for potential expansion.

City of Fargo’s Effluent Reuse Facility (ERF) reverse osmosis skids with associated process piping.

The supply and return pipelines stretch across developed and rural areas of Cass County. The pipelines consist of a 12-inch water supply line and an 8-inch return line, both made of continuously fused high-density polyethylene (HDPE), a material widely used in water applications for its reliability and fewer field disturbances due to the lack of joints, significantly reducing the potential for leaks. NDSP will operate the soybean processing facility, Cass Rural Water District (CRWD) will manage the pipelines, and the City of Fargo will operate the ERF.

12” supply and 8” return water pipelines strung out prior to fusion.

While water reuse is more commonly implemented in more arid regions of the country, reuse provides a strategic advantage for industries and water utilities in the Upper Midwest. Incorporating reuse of water reduces dependence on fresh sources, insulating operations against future variability in supply and regulatory changes. Beyond reliability, reuse lessens the environmental footprint by reducing withdrawals and protecting aquatic ecosystems, while also positioning industries as leaders in sustainable practices.

“This unique project exemplifies how innovative thinking, and strong partnerships can deliver sustainable water solutions for agribusiness. By adopting water reuse, we’re advancing resilient water practices that benefit communities and industries alike,” says Kellen Grubb, AE2S Project Manager.

NDSP’s new facility not only reduces the demand on local source water supplies but also strengthens the local economy by supporting new job creation and reducing transportation costs for soybean growers. For the City of Fargo and CRWD, the project provides an additional revenue stream, stabilizing rates for their respective customers. By transforming unused land into a center of economic activity, the NDSP facility bolsters the region’s tax base and agricultural economy.

As prime consultant, AE2S managed every phase of the dual-pipeline and ERF project—planning, funding support, design, construction, and startup. Technical services included civil, process, and electrical engineering; hydraulic modeling; GIS mapping; land surveying; right-of-way acquisition and permitting; controls and SCADA programming; and commissioning.